-

Product

By product type

TH-1230

TH-1230 series LiDAR is a measurement type single line LiDAR that supports indoor and outdoor applications. This product has stronger interface and structural universality, and overall higher cost-effectiveness. For the target of 10% reflectivity, its effective measurement distance reaches 30 meters. The LiDAR adopts industrial grade protection design and is suitable for scenarios such as highways, ports, railways, and electricity that require strict reliability and high performance.

TH-1230 PLUS

The TH-1230 PLUS series LiDAR is a high-performance measurement type single line LiDAR, suitable for various indoor and outdoor application scenarios. The LiDAR adopts industrial grade protection design, ensuring its stable operation in high-precision and high reliability requirements such as mine card obstacle avoidance, positioning, loading monitoring, automatic feeding, level height measurement, level volume calculation, and 3D point cloud construction. Its scanning frequency can reach up to 100Hz, and its angular resolution is as low as 0.0625 °, fully meeting the high-performance requirements of these applications.

TH-1230

TH-1230 series LiDAR is a measurement type single line LiDAR that supports indoor and outdoor applications. This product has stronger interface and structural universality, and overall higher cost-effectiveness. For the target of 10% reflectivity, its effective measurement distance reaches 30 meters. The LiDAR adopts industrial grade protection design and is suitable for scenarios such as highways, ports, railways, and electricity that require strict reliability and high performance.

TH-1230 PLUS

The TH-1230 PLUS series LiDAR is a high-performance measurement type single line LiDAR, suitable for various indoor and outdoor application scenarios. The LiDAR adopts industrial grade protection design, ensuring its stable operation in high-precision and high reliability requirements such as mine card obstacle avoidance, positioning, loading monitoring, automatic feeding, level height measurement, level volume calculation, and 3D point cloud construction. Its scanning frequency can reach up to 100Hz, and its angular resolution is as low as 0.0625 °, fully meeting the high-performance requirements of these applications.

TH-K20

TH-K20 LiDAR is a single line LiDAR designed specifically for obstacle avoidance, which is suitable for both indoor and outdoor environments. Its maximum scanning angle range reaches 270 °, the scanning frequency can reach up to 50Hz, and the angular resolution is fine to 0.125 °. This LiDAR adopts industrial grade protection and anti vibration design to ensure that it can meet extremely strict requirements for accuracy and reliability in applications such as AGV obstacle avoidance and electric vehicle collision prevention.

TH-K40

TH-K40 LiDAR is a measurement type single line laser radar, while is suitable for bulk scanning applications, with an effective measurement distance of up to 40 meters. The maximum scanning angle range is 270 °, the scanning frequency is locked at 25Hz, and the angular resolution is locked at 0.0625 °. The LiDAR adopts industrial grade protection design, which can meet the strict reliability and high performance requirements of applications such as automatic feeding, material level height, material level volume, and three-dimensional point cloud.

TH-K60

TH-K60 LiDAR is a measurement type single line laser radar, while is suitable for bulk scanning applications, with an effective measurement distance of up to 60 meters. The maximum scanning angle range is 270 °, the scanning frequency is locked at 25Hz, and the angular resolution is locked at 0.0625 °. The LiDAR adopts industrial grade protection design, which can meet the strict reliability and high performance requirements of applications such as automatic feeding, material level height, material level volume, and three-dimensional point cloud.

TH-K100

TH-K100 LiDAR is a measurement type single line laser radar, while is suitable for bulk scanning applications, with an effective measurement distance of up to 100 meters. The maximum scanning angle range is 270 °, the scanning frequency is locked at 25Hz, and the angular resolution is locked at 0.0625 °. The LiDAR adopts industrial grade protection design, which can meet the strict reliability and high performance requirements of applications such as automatic feeding, material level height, material level volume, and three-dimensional point cloud.

TH-9430

The TH-9430 LiDAR is designed as a 3D scanning device specifically for the application of bulk material inventory in silos in dusty and dirty environments. This device has excellent measurement capabilities, with a measurement distance of up to 30 meters; Video image format support 1920x1080@20fps. The TH-9430 LiDAR also has the explosion-proof mark ExtblllCT130 ° CDb, ensuring safe use under specific conditions. The whole machine adopts industrial grade protection design, which can fully meet the strict requirements of safety and reliability in these specific scenarios of related industries.

TH-9460

The TH-9460 LiDAR is designed as a 3D scanning device specifically for the application of bulk material inventory in silos in dusty and dirty environments. This device has excellent measurement capabilities, with a measurement distance of up to 60 meters; Video image format support 1920x1080@20fps. The TH-9460 LiDAR also has the explosion-proof mark ExtblllCT130 ° CDb, ensuring safe use under specific conditions. The whole machine adopts industrial grade protection design, which can fully meet the strict requirements of safety and reliability in these specific scenarios of related industries.

TH-94100

The TH-94100 LiDAR is designed as a 3D scanning device specifically for the application of bulk material inventory in silos in dusty and dirty environments. This device has excellent measurement capabilities, with a measurement distance of up to 100 meters; Video image format support 1920x1080@20fps. The TH-94100 LiDAR also has the explosion-proof mark ExtblllCT130 ° CDb, ensuring safe use under specific conditions. The whole machine adopts industrial grade protection design, which can fully meet the strict requirements of safety and reliability in these specific scenarios of related industries.

TH-K60

TH-K60 LiDAR is a measurement type single line laser radar, while is suitable for bulk scanning applications, with an effective measurement distance of up to 60 meters. The maximum scanning angle range is 270 °, the scanning frequency is locked at 25Hz, and the angular resolution is locked at 0.0625 °. The LiDAR adopts industrial grade protection design, which can meet the strict reliability and high performance requirements of applications such as automatic feeding, material level height, material level volume, and three-dimensional point cloud.

TH-K10

TH-K10 LiDAR is a measurement type single line LiDAR suitable for indoor and outdoor environments. Its features include a maximum scanning angle range of 300 °, a scanning frequency of up to 50Hz, and an angle resolution as low as 0.075 °. In addition, the LiDAR adopts industrial grade protection design to ensure that it can meet the high demand for accuracy and reliability in industry application scenarios, such as being recommended for "conveyor belt operation status monitoring applications".

-

Industries

Industries

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

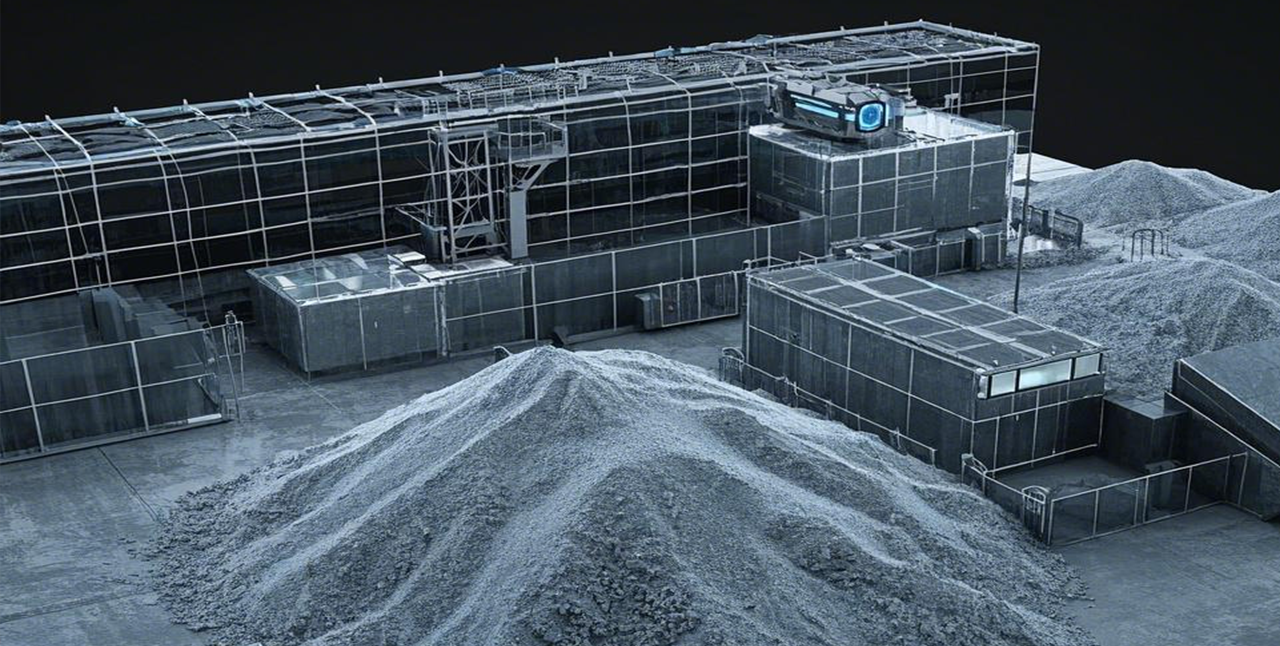

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

Mining&Coal

LiDAR technology significantly enhances safety and efficiency in mining and coal operations. It is used for high-precision surveying of pits and stockpiles, monitoring unstable slopes for potential collapses, and creating detailed 3D models for volume calculations and planning, all while keeping personnel at a safe distance.

Metallurgy & Steel

LiDAR is vital for precision and safety in metallurgy and steel plants. It continuously monitors the structural integrity of critical assets like blast furnaces and ladles, measures stockpile volumes of raw materials, and guides automated cranes. This non-contact 3D scanning ensures operational efficiency, predictive maintenance, and enhanced worker safety.

Agriculture & Food

In agriculture and the food industry, LiDAR technology is revolutionizing precision farming and operational efficiency. Its non-contact, high-resolution 3D sensing capabilities are applied across the entire chain—from field mapping and crop monitoring to processing plant automation and inventory management of bulk commodities like grain.

Building materials & Cement

In the building materials and cement industry, LiDAR technology serves as a cornerstone for digitalization, safety, and process optimization. It is extensively used from quarry management and plant digitization to final product inventory and dispatch, transforming operations through precise, non-contact 3D measurement.

-

Learn & Support

Learn & Support

-

About

- Contact us